Scarifying Alberta’s forests with the Bracke Forest 24.a mounder. We’re the first company in Canada operating the Swedish-made technology for the silviculture industry.

YEAR-ROUND services

summer mounding

Our summer equipment includes three John Deere 748H skidders with attached Bracke Forest 24.a mounders. Flotation tires are installed for low soil impact. We produce 1,000 – 1,800 mounds per hectare and average 15 hectares per day.

winter RIPPER plowing

Our winter operation includes two Caterpillar D8 dozers. Both come with an attached custom-made V-plow and ripper that scarifies rows into the frozen soil. We produce cuts on average of 6 hectares per day.

our work in action

“We’ve been in the scarifying industry since 2016 and considered to be the top site prep contractor in Alberta, Canada with a stellar health and safety record.”

~ Larry Zeller ~

mounder features

wheels

Two 3-pronged mattock wheels dig into the soil to lift and create mounds of exposed mineralized soil. The wheels rotate in proportion to machine speed ensuring proper spacing between each mound. Competing vegetation is controlled and water collects in a divot left by the mound to moisturize tree seedlings.

arms

The mounder arms are articulated laterally and can move from side to side when obstacles come in their path. The lift arm hinges are a new design that provides not only a good lift height when backing up but arms can also be lifted separately if the operation requires. The hydraulics are load sensing for ease of operation.

controls

The mounder is fitted with sensors that communicates information from the wheels to the control system inside the cab. One of 8 operating profiles is selected to achieve the best planting spots for the site concerned. It keeps track of the number of mounds per cutblock and the total number of hours worked.

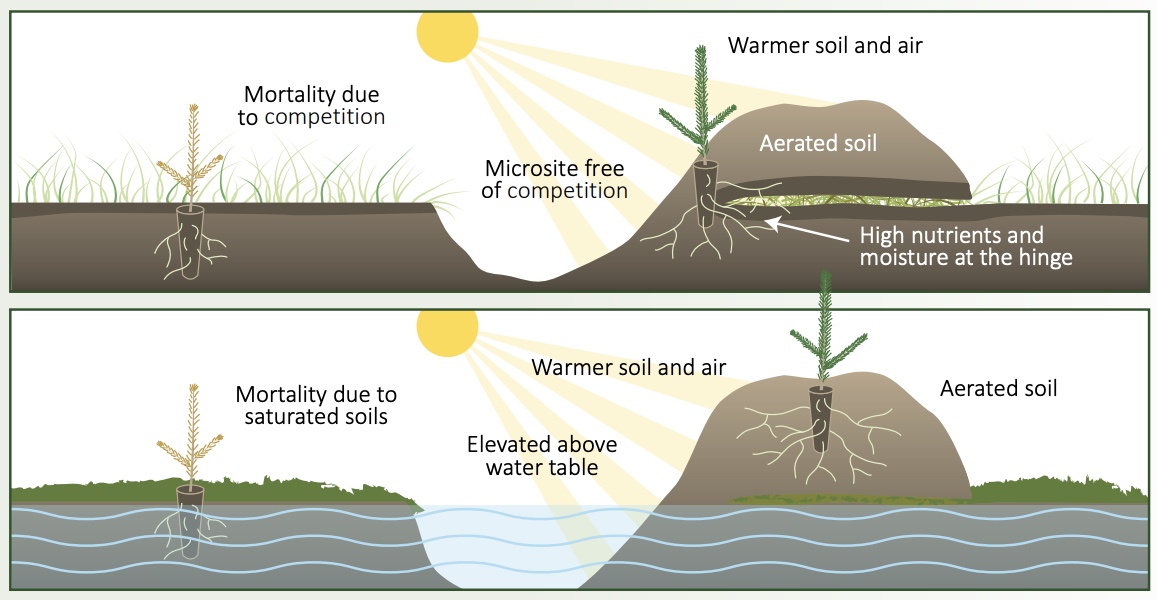

ADVANTAGES OF MOUNDING

Reference from A Guide to Mounding, Natural Resources Canada

companies we have worked with

BRISCO WOOD

PRESERVERS LTD.

why choose us

QUALITY

We set our standards high so clients receive top quality work. This ensures customer confidence, seals our reputation, and benefits the silviculture industry as a whole.

VERSATILITY

We know there are times when environmental conditions and client requirements can change. That’s why we step up to accommodate every need accordingly.

EXPERIENCE

We have well-trained operators who provide prompt and efficient execution on all cutblocks. This commitment assures our clients receive utmost value in production and return.

about us

Having consulted in the oil and gas industry globally for over 30 years, our focus changed in 2016 when we realized there was an opportunity for site prep operations in Alberta, Canada. We purchased a D8R dozer and worked the winter scarifying.

With that experience under our belt, we set out to make our operations year round. We acquired a skidder/mounder unit for the ensuing summer season but soon discovered the equipment did not meet up to our standards. So, we upgraded to a John Deere 748H skidder and installed a Bracke 24.a mounder. It was the right move! Confident in our ability for growth we expanded with another mounding unit and D8T dozer in 2019. In 2021, we added a third mounding unit. We welcome new clients anywhere in Alberta!

operations

Larry Zeller

780-913-6660

operations@lze.ca

administration

Felice Zeller

780-914-8306

admin@lze.ca

PO Box 3137

Spruce Grove, AB

T7X 3A5

for visiting us!